Composite Materials

Composite materials are composed of two or more materials that have different properties. The materials are bonded together and their properties are combined.

They combine the physical properties of the individual materials they are made up of, forming a superior material.

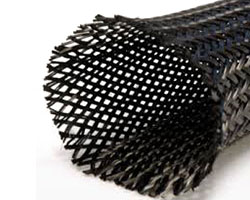

Polymers can be strengthened by including other material such as glass, carbon fibre and Kevlar. The earliest forms of composite materials were straw and mud combined to form bricks for building construction.

One of the most well-known composites on the market is reinforced plastic. Now, in most products today plastic is used in a pure form like in toys and water bottles, but it can be reinforced with fibers from other materials to make some of the strongest, lightest, and most versatile composites to date.

Today, composites can be:

Wood based Composites

Name |

Features |

Fact |

Strength |

Weaknesses |

Types and their uses |

Plywood |

Softwood ply manufactured from softwood such as pine and spruce. But hardwood ply is made from more durable hardwood such as birch ply and veneers. |

Different types of plywood are available specifically for different uses. Marine Ply is rot resistant, steam resistant and used in boat construction. |

Relatively strong due to the veneer grain layered in opposite directions. Light weight. |

Prone to rot. Internal use only. Can chip when sawing. |

Indoor building material, flooring. |

MDF |

No grain, speckled brown sandy colours. |

No surface grain as MDF is made up of fibres. |

Good density. No knots or imperfections drilled/milled very easily. Finishes well with paint when sealed. |

Urea Formaldehyde is used to combine the particles which irritate eyes and cause breathing problems. |

Model making, doors, shelving. |

Chipboard |

No grain but large visible chips layered on top of each other, light in colour. |

Fashionable low priced furniture stores such as IKEA rely on cheaper materials such as chipboard. |

Cheap. Durable when laminated. |

Expands when in contact with moisture. Not suitable for external use. Weakest manufactured board. |

Fire doors, kitchen worktops (with a laminate. |

Hardboard |

Common hardboard has a uniform brown speckled pattern with the top surface being glossy and smooth, the underside is matt and rough. |

Oil-tempered hardboard is more durable. Perforated holes also known as pegboard are used to hang tools. |

Will not split or crack. Durable. Cheap. |

Not suitable for outside use. Expands when in contact with moisture. |

Paint boards, furniture production. |