Shape Memory Alloy

‘A shape-memory alloy (SMA, smart metal, memory metal, memory alloy, muscle wire, smart alloy) is an alloy that "remembers" its original shape and that when deformed returns to its pre-deformed shape when heated.’

Nitinol (or SMA wire) is made up of nickel and titanium. It can be shaped and bent as easily as any ordinary wire but has characteristics and properties that make it unique. It is also very expensive as compared to copper or steel wire.

The wire has a memory and will return to its original shape if heated to above 90 degrees (centigrade).

The material can also remember a shape and can be achieved by folding the wire to the desired shape and clamping it in position.

After the wire has been heated for five minutes at 150 degrees (centigrade) an electric current is passed through. If the wire is now folded into another shape and then placed in hot water it returns to the original shape.

Uses

Nitinol is a smart alloy and has a range of uses including dental braces, frames for glasses and stents:

-

Dental braces can be made from Nitinol and force the teeth gently into place by exerting pressure.

By Monica Nguyen from united states (week 4)

[CC BY 2.0 (http://creativecommons.org/licenses/by/2.0)], via Wikimedia Commons -

Spectacle frames made of Nitinol are very versatile and will return to their original shape if deformed through accidental damage.

-

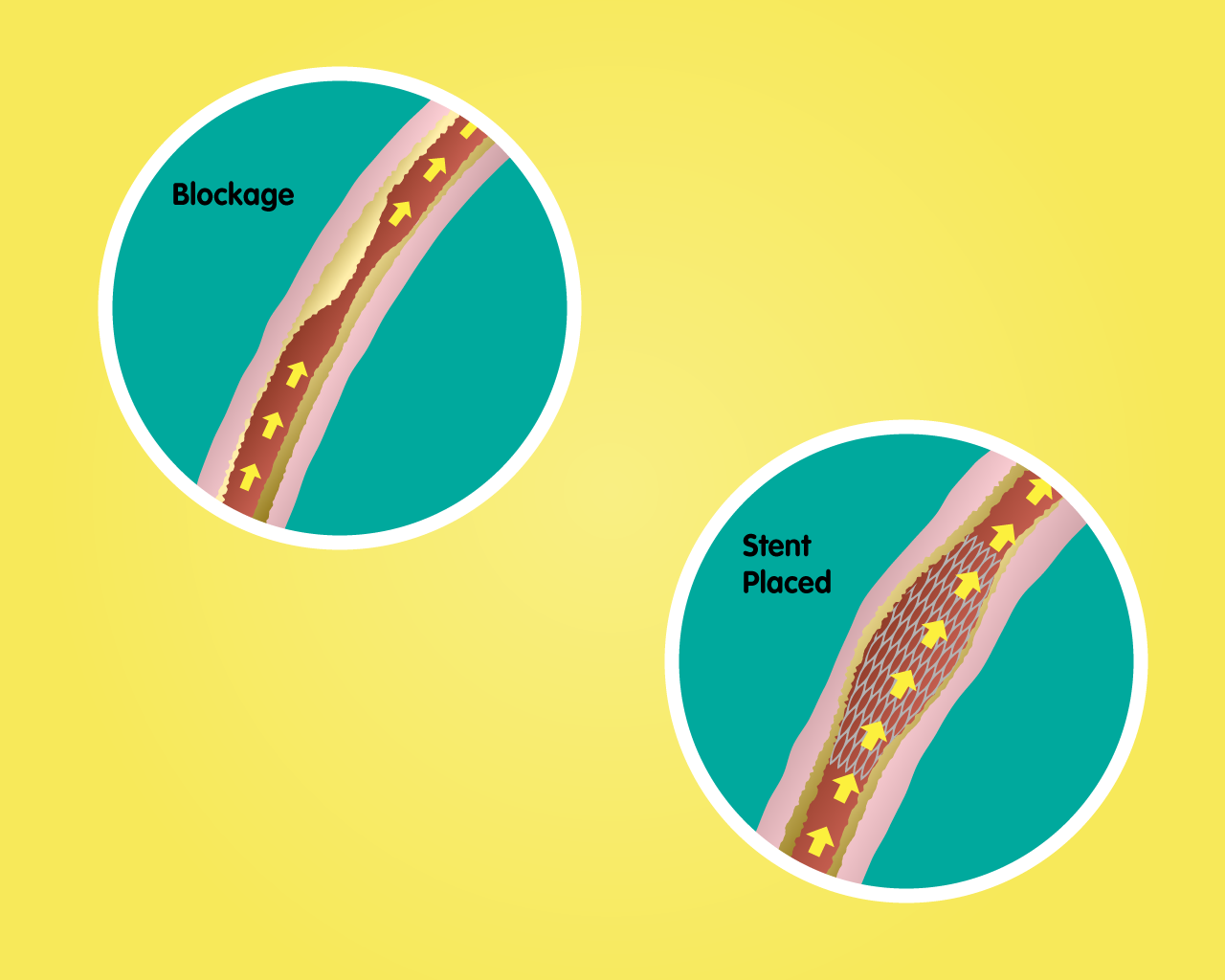

Stents are tubes that are inserted into damaged blood vessels and expand or open out (actually reacting to body temperature) when in position allowing blood to flow smoothly.

Disassembly

SMA’s can be used to manufacture fasteners or actuators within a product during the manufacturing stage. After the products' useful life the products are then treated by being exposed to what is called a ‘transformation temperature.’

The product then splits apart caused by the SMA. This can be a fastener inside the product. This active disassembly makes it easier to disassemble a product and reduce costs through a temperature change.

This saves on robotic or hand disassembly and can be undertaken on an assembly line making disassembly very simple. This is called self disassembly through a temperature change causing the product to disassemble.

- Reduces complexity

- Less costs to dismantle

- Temperature change

- Triggering the smart material

- Releasable fasteners made form SMAs

- Splits apart the product

- No hand disassembly or robotics required