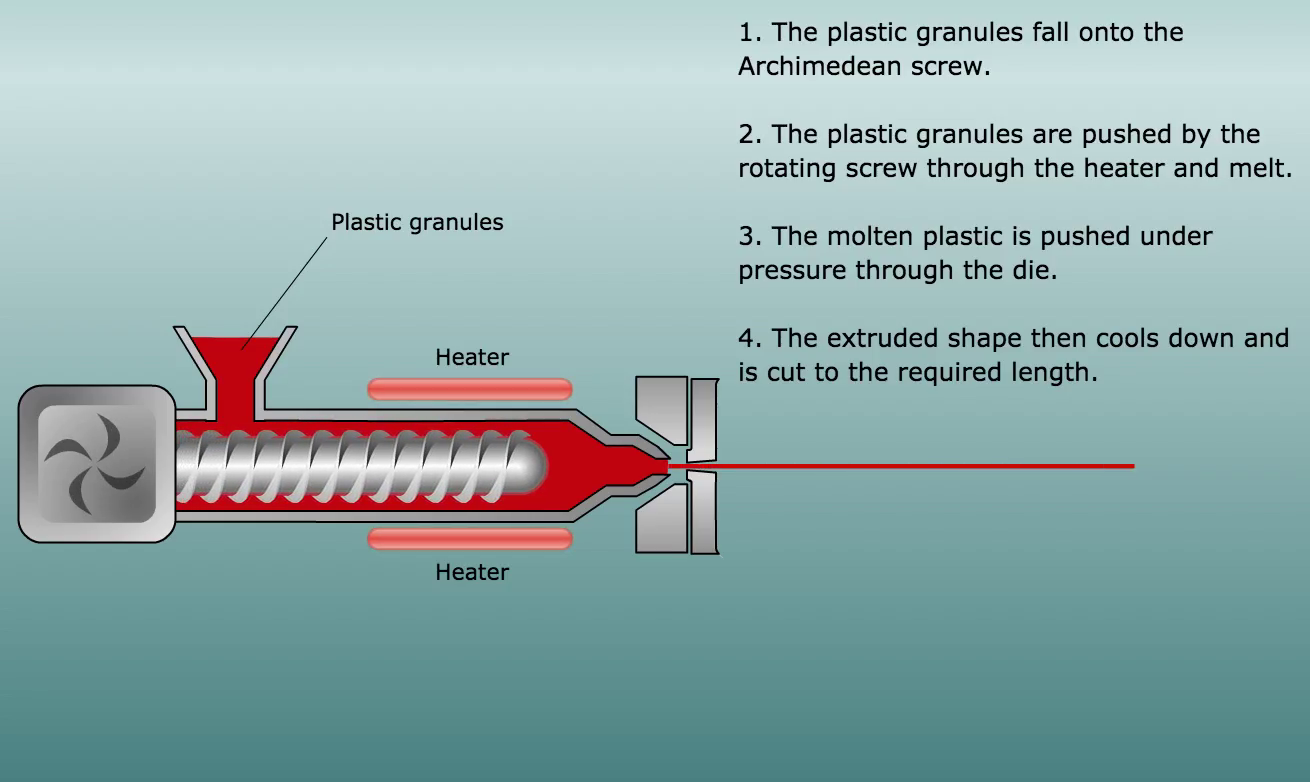

Extrusion Moulding

Extrusion is a very similar process to injection moulding but uses a die instead of a mould. The shaped die produces continuous lengths of a thermoplastic product.

Extrusion produces products such as guttering, uPVC windows and pipes. The typical plastics used are PVC (polyvinylchloride), Nylon and Polythene.

- The thermoplastic granules from the hopper fall onto the Archimedean screw.

- The rotation screw takes the plastic past the heater.

- The molten plastic is passed through the die and is cooled.

- The process is continuous.

- The product is cut into the desired size later on in the process.

- Extruded products are usually simple shapes.

| Advantages | Disadvantages |

|---|---|

|

|

Resources

Pipes

Vacuum Forming