Mechanisms and Calculations

A mechanism is simply a device which takes an input motion and force, and outputs a different motion and force. The point of a mechanism is to make the job easier to do. The mechanisms most commonly used in mechanical systems are levers, linkages, cams, gears, and pulleys.

You need to know how to calculate the mechanical advantage obtained by using levers, the velocity ratio in levers and pulley systems, and gear ratio and output speed when using gears.

Mechanical advantage

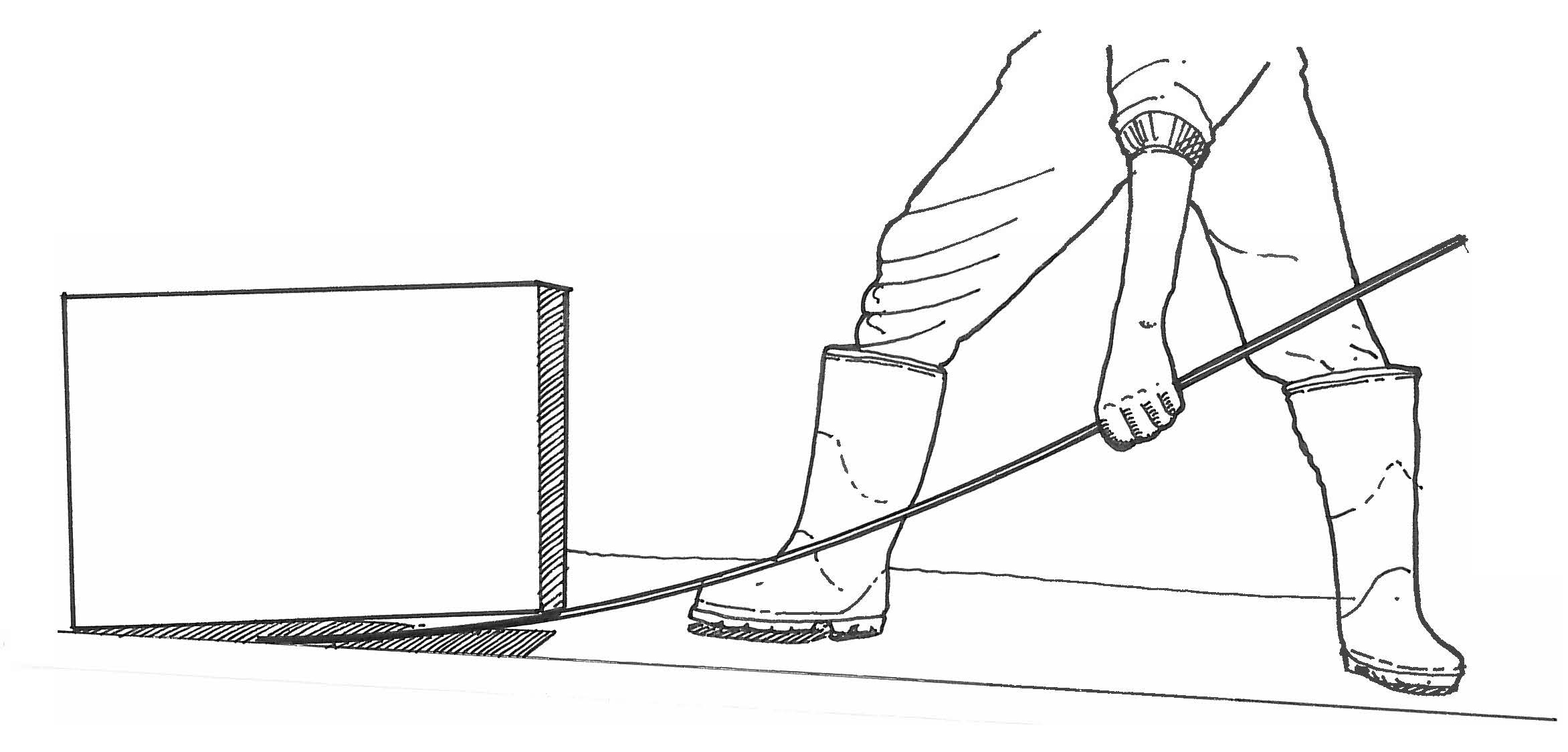

Class 1 and class 2 levers both provide mechanical advantage. This means that they allow you to move a large output load with a small effort. Load and effort are forces and are measured in Newtons (N). Mechanical advantage is calculated as follows:

Mechanical Advantage = load ÷ effort

In the example above, where the load = 500N and the effort = 100N, the mechanical advantage would be:

500N ÷ 100N = 5

Velocity ratio

The mechanical advantage gained with class-one levers and class-two levers makes it seem like you are getting something for nothing: moving a large load with a small effort. The catch is that to make the effort smaller, you have to move a greater distance. In the first diagram the trade-off is that you need to push the lever down further to move the load up a smaller distance. This trade-off is calculated by the velocity ratio:

Velocity Ratio = distance moved by effort ÷ distance moved by load

Cams

A cam is a shaped piece of metal or plastic fixed to a rotating shaft. A cam mechanism has three parts: cam, slide and follower.

The cam shaft rotates continually, turning the cam. The follower is a rod that rests on the edge of the turning cam. The follower is free to move up and down, but is prevented from moving from side to side by a slide or guide, so the follower can only do three things:

- Rise (move up)

- Fall (move down) or

- Dwell (remain stationary)

The follower's pattern of movement depends on the profile or outside edge of the cam that it follows.

Gears

Gears consist of toothed wheels fixed to shafts. The teeth interlock with each other, and as the first shaft (the driver shaft) rotates, the motion is transmitted to the second or driven shaft. The motion output at the driven shaft will be different from the motion input at the driver shaft - in place, speed, direction and other ways.

A number of gears connected together are called a gear train. The input (e.g. a motor) is connected to the driver gear. The output is connected to the driven gear.

Gear ratio and output speed

Where there are two gears of different sizes, the smaller gear will rotate faster than the larger gear. The difference between these two speeds is called the velocity ratio, or the gear ratio, and can be calculated using the number of teeth. The formula is:

Gear Ratio = number of teeth on driven gear ÷ number of teeth on the driver gear.

So the gear ratio for the simple gear train above, if the smaller gear is the driver gear, is:

Gear ratio = 60 ÷ 15 = 4.

In other words, the driver gear revolves four times to make the driven gear revolve once.

If you know the gear ratio, and the speed input at the driver gear, you can calculate the speed output at the driven gear using the formula:

Output speed = input speed ÷ gear ratio

So if the gear ratio is 4 and the driver gear is revolving at 200 rpm then the output speed = 200 ÷ 4 = 50 rpm

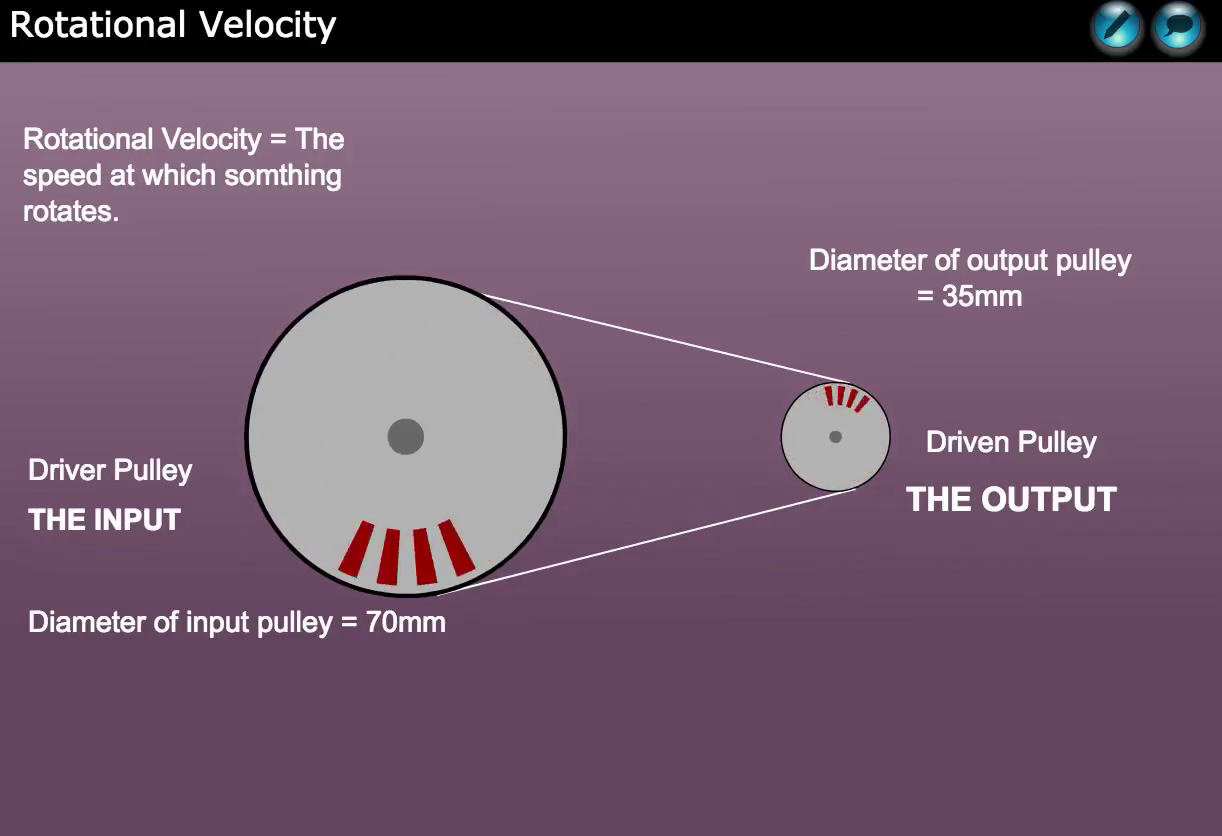

Pulley systems

Pulleys are used to change the speed, direction of rotation, or turning force or torque. A pulley system consists of two pulley wheels each on a shaft, connected by a belt. This transmits rotary motion and force from the input, or driver shaft, to the output, or driven shaft.

If the pulley wheels are different sizes, the smaller one will spin faster than the larger one. The difference in speed is called the velocity ratio. This is calculated using the formula: Velocity Ratio = diameter of the driven pulley ÷ diameter of the driver pulley

If you know the velocity ratio and the input speed of a pulley system, you can calculate the output speed using the formula:

Output speed = input speed ÷ velocity ratio